Crafting With Bioplastics

Since Summer 2025, I have been developing techniques for creating organically-colored bioplastic sheets, which I laser cut and assemble into woven pieces. Through experimentation with different casting surfaces, I discovered that pouring bioplastic onto holographic sheets produces holographic bioplastics, a finding inspired by researching the holographic chocolate manufacturing processes.

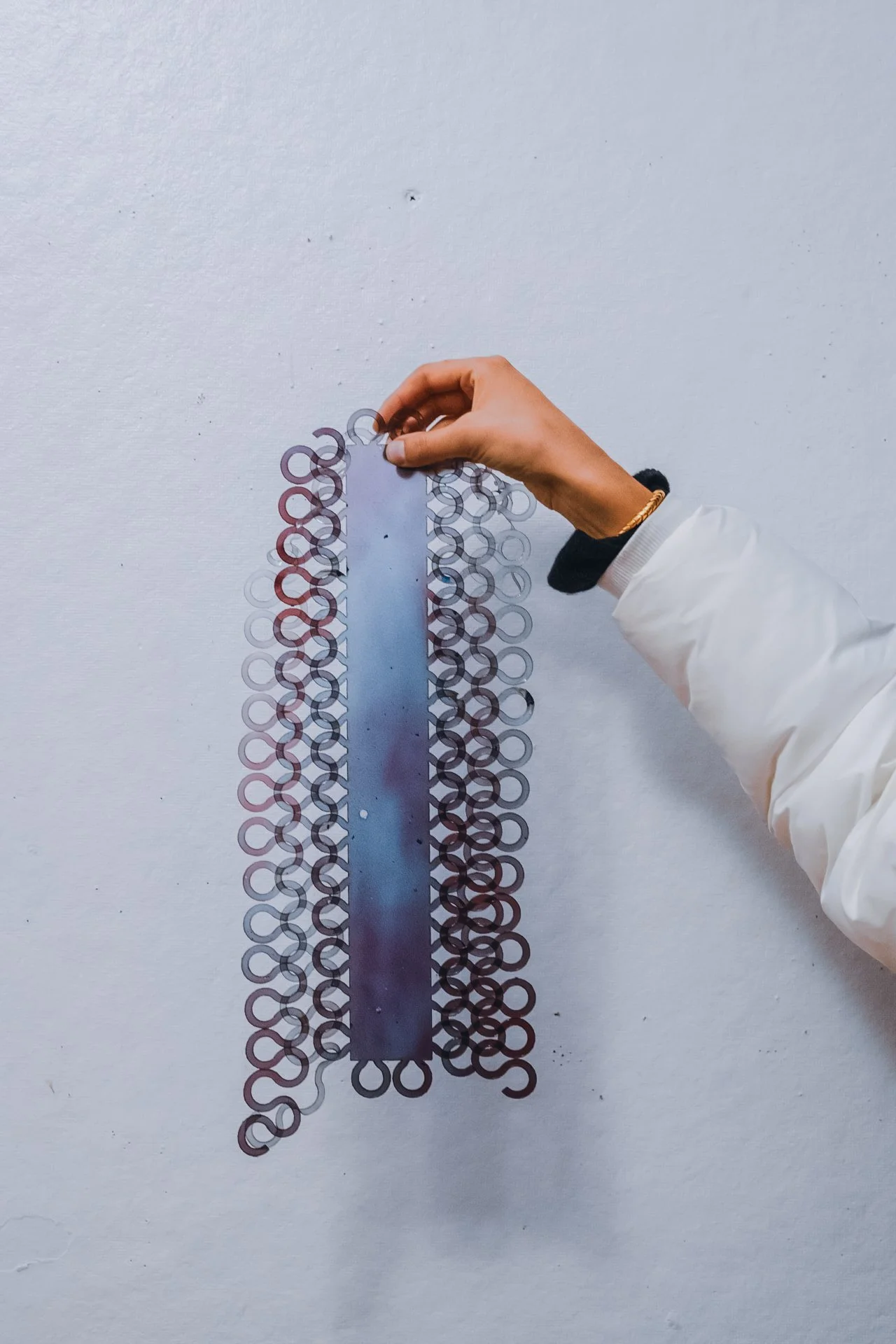

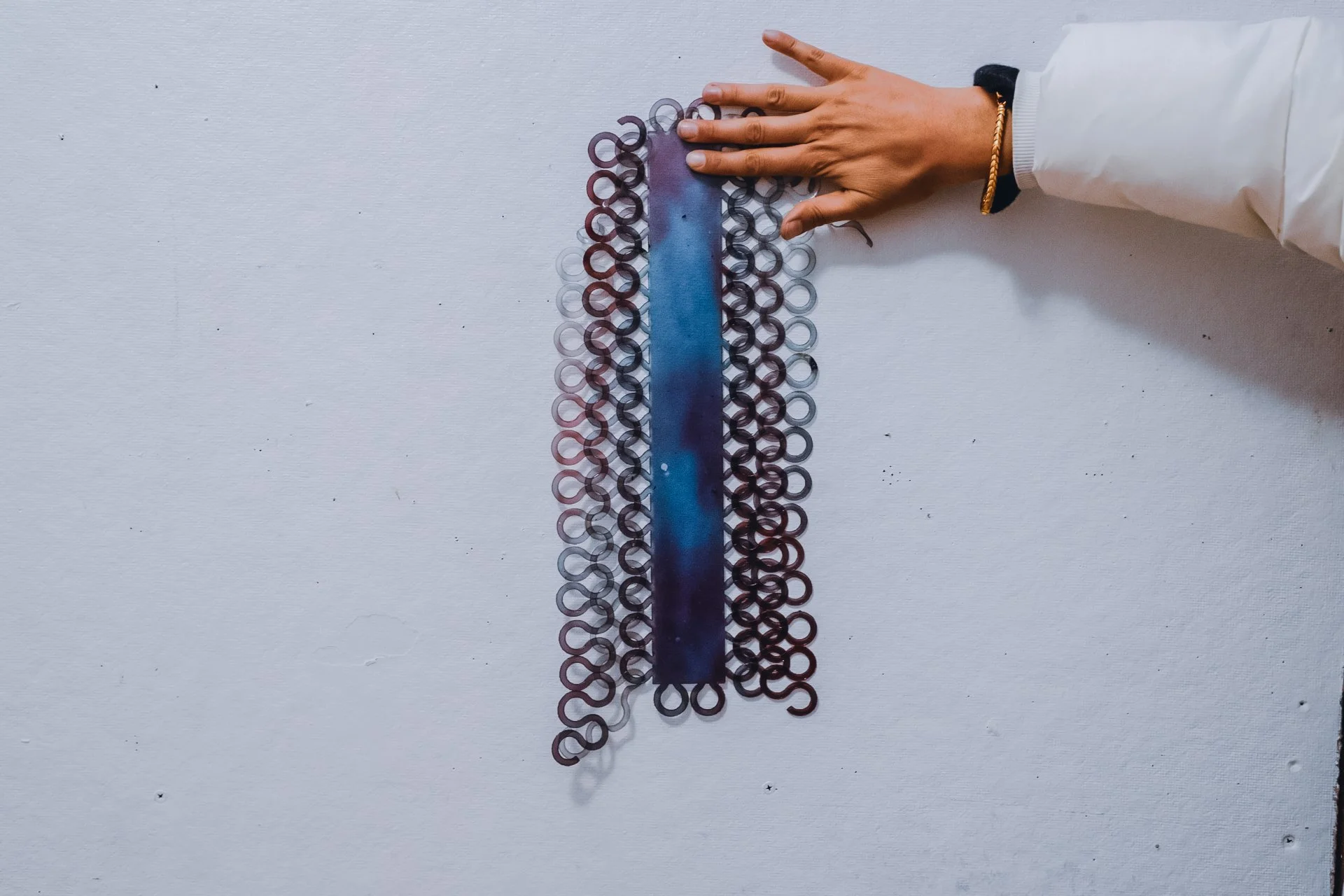

Woven Lattice in Spirulina Blue, 2025

woven, laser-cut gelatin bioplastic

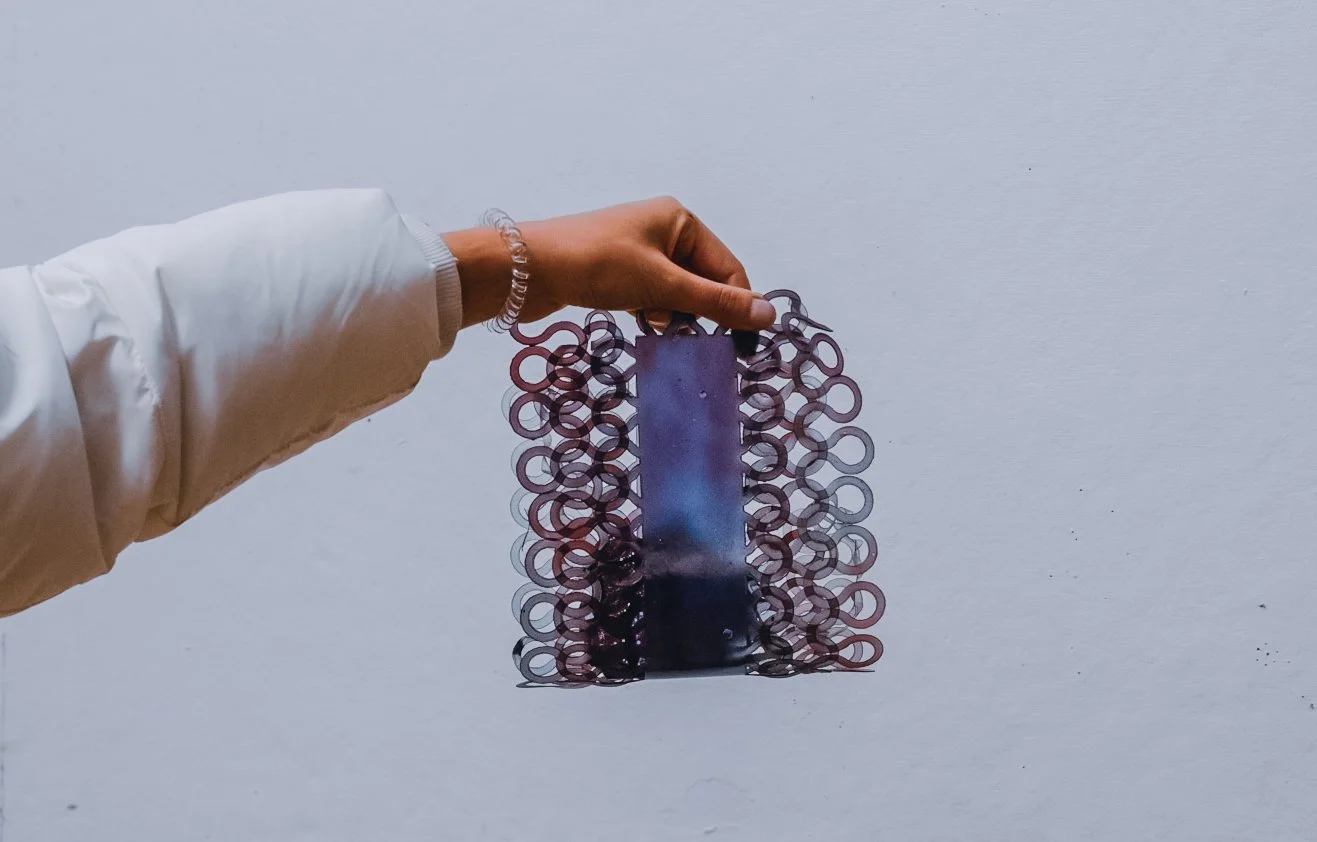

Cabbage-Spirulina Marbling III, 2025

gelatin bioplastic with blue spirulina and red cabbage

Cabbage-Spirulina Marbling III, 2025

gelatin bioplastic with blue spirulina and red cabbage

Cabbage-Spirulina Marbling III, 2025

gelatin bioplastic with blue spirulina and red cabbage

Woven Lattice in Spirulina Blue, 2025

woven, laser-cut gelatin bioplastic

Process Innovations

My work explores sustainable material fabrication through gelatin-based bioplastics colored with natural pigments including red cabbage powder and blue spirulina. A key breakthrough involved establishing safe protocols for laser cutting bioplastics, working with Nirmal Kumar to determine appropriate settings (speed 36, power 80, which is similar to leather cutting parameters) and safety measures. We found that placing a thin acrylic sheet beneath the bioplastic during cutting prevents bed contamination while producing minimal odor.

Successfully casting large-format sheets enables new possibilities for color exploration and marbling techniques. The ability to laser cut intricate geometries directly into bioplastic sheets significantly reduces both time and material waste compared to casting into pre-cut acrylic molds.

Holographic Diffraction Study No. 1, 2025

cast gelatin bioplastic

Ongoing Research

Current explorations include documenting the bioplastic drying process through timelapse photography, expanding the range of assemblies and woven structures, and further investigating natural color combinations and marbling effects. This research was supported by a Frank-Ratchye Further Fund (FFRF) grant.

Acknowledgments

Thanks to Audrey Reiley for casting and marbling collaboration; Nirmal Kumar for laser cutting support; Terry Hritz for enabling material experimentation in the dFAB Lab; Dana Cupkova for teaching the Shaping Environments course from which these experiments emerged; and the Frank-Ratchye Studio for Creative Inquiry for project support.